【Model】: Q38,Q48,Q58

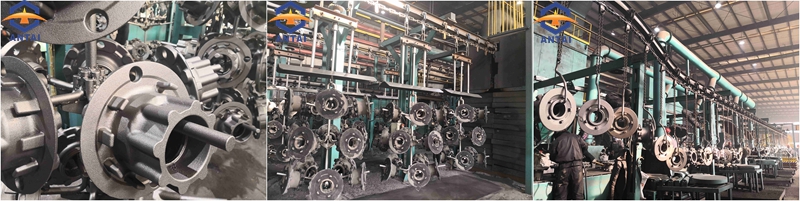

【Application】: Surface cleaning and strengthening of castings, forgings, heat-treated parts and steel structural parts, especially for automotive parts, tractor parts, diesel engine casings, motor casings, engine blocks, engine cylinder heads and valves.

【Characteristics】: Labor, high productivity.

The working princile of continuous overhead monorail shot blasting machine( also named as suspended chain shot blasting machine) is that the workpieces can be continuously operated or stepped with the hanging chain or the advanced power and free type can be used to transported workpieces. So that the workpieces can be stopped at the loading and unloading areas respectively to realize loading, unloading and blasting on the fixed points. Lifting capacity 50~2000kgs at the single point, high productivity, reliable operation, suitable for large scale cleaning of various types of easy hanging parts, such as, engine cylinder head, cylinder cover, motor casings, gears, motorcycle enginer casings, locomotive hook frame assembly, bogie assembly, hardware too housing and water pump. It's the ideal choice for automobile, tractor, diesel engine, motor and valve industries, and can be designed and manufactured according to users' requirements.

The continuous overhead rail shot blasting machine is a kind of single stroke catenary continous type shot blasting machine, which has advantages of static loading and unloading of workpieces, automatic fast conveying and positioning, workpieces rotating and blasting. It's suitabe for all-round shot blasting of large quantities of steel castings, iron castings and welding parts. Not only can the rust and slags on the surface of workpieces be removed, but also the welding stress of workpieces can be eliminated, and finally improve surface and intrinsic quality of the entire workpieces, widely used in metallurgy, petroleum, chemical, machiner and other industries.

Q385 Valves Continuous Overhead Monorail Shot Blasting Machine

Q483 Engine Block Continuous Overhead Monorail Shot Blasting Machine

Q485 Railway Parts Robotic Continuous Overhead Monorail Shot Blasting Machine

Q485 Aluminum Alloy Castings Continuous Overhead Rail Shot Blasting Machine

Q485 Brake Drum,Brake Disc Truck Parts Continuous Overhead Monorail Shot Blasting Machine

Q5810 Brak Drum,Brake Disc Truck Parts Continuous Overhead Monrail Shot Blasting Machine

Suitable for large scale cleaning of various types of easy hanging parts, such as, engine cylinder head, cylinder cover, motor casings, gears, motorcycle enginer casings, locomotive hook frame assembly, bogie assembly, hardware too housing and water pump. It's the ideal choice for automobile, tractor, diesel engine, motor and valve industries, and can be designed and manufactured according to users' requirements.

| Item | Q383 | Q384 | Q385 | Q483 | Q485 | Q4810 | Q583 | Q5810 |

Productivity(Hook/hour) | 50,65,38,49 | 70,80 | 75 | 10 | 10 | 10 | 10 | 10 |

Size of work pieces(mm) | φ500*1200 φ700*1200 | φ700*1500 | φ700*1200 | φ1000*1400 | φ1200*1700 | φ700*2400 | φ1000*1500 | φ750*2400 |

Max weight of work pieces (Hook/hour) | 250 | 400 | 500 | 300 | 500 | 800 | 300 | 1000 |

Hook running speed (m/min) | 0.5, 0.65 | 0.8, 0.93 | 0.65 | 2.44 | 7.34 | 2.44 | VFD | VFD |

Chain spacing (mm) | 600,800 | 800 | 800 | 2560 | 2560 | 2560 | 1000 | |

Blasting capacity (kg/min) | 4*250 | 6*250 | 5*250 | 2*250 | 3*250 | 6*360 | 4*250 | 6*360 |

Ventilation capacity(m3/h) | 18000 | 26500 | 23700 | 6000 | 10000 | 25000 | 18000 | 25000 |

Power(without dust collecting)(kw) | 75.3 | 122.6 | 106.75 | 38.75 | 58.43 | 85 | 127.25 | 160 |

1. The hooks are equially spaced, continuous speed advancement, continuous operation, high production efficiency, and can realize fixed-point cleaning of workpieces and fixed-point loading and unloading.

2. Pneumatic doors on the entrance and exit of shot blasting machine, good chamber sealing performance.

3. The length and arrangement of the chains can be set according to requirements of users. The working points of loading and unloading castings are fixed, and it's easier to form a flow operation with the upper and lower processes.

4. The shot blasting chamber adopts all steel protection, long service life and lower maintenance.